2024年莫斯科国际机床及工具展览会

-

日期:2024-05-20~2024-05-24

-

城市:莫斯科

-

展馆:莫斯科国际展览中心

-

主办:莫斯科国际展览有限公司

-

俄罗斯莫斯科国际机床及工具展览会(metalloobrabotka)是国际金属加工工业设备、仪器和工具专业展览会,也称俄罗斯国际机床展,该展由俄罗斯机床工具协会以及Expocentre展览中心共同主办,并得到俄罗斯工业贸易部、俄罗斯工业家和企业家联盟以及欧洲机床工业合作协会支持。该展览会于1984年开始举办,每年一届,在莫斯科国际展览中心举行。该展是俄罗斯及东欧地区有规模和影响力的机床专业展览会。根据其规模和效果,已经成为欧洲十大工业展会之一。德国机床协会,瑞士机床协会,意大利机床协会,西班牙机床协会,台湾机床协会等每届均组织大规模国家展团参加该展。

metalloobrabotka是机床、工具和金属加工行业主要的国际展会,拥有超过30年的成功经验,在所有全球一体化的趋势下,来自行业的领导者汇聚在一个展览中心,与30年的专业人士聚集在一起,66%的访客寻找商业伙伴,44%寻找供应商,约87%的参展商积极评估销售线索,约99%积极评估事件管理,87%的常规参展商,多年来,metalloobrabotka促进业务发展并帮助创造新的销售机会。

市场情况:近年来,作为“金砖四国”之一的俄罗斯经济取得巨大成就,机械市场需要不断加大,前八年俄罗斯机械市场规模已增长至1274.9亿美元,并逐年在增加,特别是最近欧美市场不确定性,俄罗斯及东欧市场相对稳定高增长。其中中国对俄罗斯机械出口呈上升态势,如前七年每年中国对俄罗斯机械出口额已达92亿美元,占俄罗斯机械市场总进口额的17%,并在持续快速增长,俄罗斯已成为国内机械行业第八大出口市场国。中国产品在俄罗斯市场已得到足够认可,对于中国出口商来说,应高度重视俄罗斯市场需求扩大、前景看好的发展趋势。总体来说,俄罗斯市场对于中国机械来说具有“潜力无限,新兴市场,恰逢良机,未来展望”外部机遇。

莫斯科是全俄最大的综合性工业城市,工业部门齐全,其中重工业与化学工业很发达,机械和仪表制造工业占全市工业总产值的一半以上。该市也是最大的军事工业中心,航空,航天,电子等工业均集中在这里。食品工业和烟草工业发展迅速。工业总产值居全国首位。机械制造业(机床、汽车、电机、仪器、钟表等)占全市工业总产值及工人数的一半以上,轻工(服装、制鞋)、纺织、化工、食品加工和印刷业亦很发达。莫斯科是一个人口超过1000万人的特大型城市,俄罗斯乃至欧亚大陆上重要得交通枢纽。同时,莫斯科还是一个重要的工业制造业中心,工业总产值居全国首位,工业门类齐全,总共拥有20000多家工厂,其中有数量众多的动力机械制作厂,以及专门制造机床,船舶,和精密仪器的厂家;同时城市还发展各种有色金属的冶炼工业,这其中铝业特别发达;除了重工业外,发达的化工业,轻工业,以及造纸业也是莫斯科工业中重要的一部分。莫斯科也是独联体最大的商业中心,俄罗斯最大的商业和金融业办事机构都设在这里。

展品范围(Show Products):

金属加工设备与技术:

1.金属切割机械:专业机床、精密机床、自动机床、半自动机床、手控wan能机床;重型机床、特殊机床、自动流水线、数控机床、多用途机床、生产模型;柔性加工单元和系统;放电加工设备,激光,等离子等非传统金属加工制造设备;

2.金属成型机械:机械压力机、液压机;自动锻造冲压机床(包括数控机器)、锻造机床;柔性数控锻造冲压机床;激光设备与技术;剪板机;折弯机;

3.铸造设备;

4.焊接设备;

5.热处理设备、涂层设备;

6.金属切割工具:切割刃;磨具、金刚石工具、其他超硬材料工具;辅助工具;工具装备系统;

7.控制和测量机器、仪器、工具:自动化生产线使用的测量装置;过程控制装置;线性和角度测量仪器;表面和形位精度控制装置;金属切割机床及工具诊断系统。

附件、装备、元件、工具、硬件和软件

数控系统和程序监控;CAE/CAD/CAM系统、程序和软件;金属加工设备;自动化设施和刀库、工作台、操作装置;工业机器人;自动化仓储;传感器、自动化配套系统;全套电子设备、驱动装置;液压和气压设备、润滑和过滤装置;减压和电动减压器;统一组件、接合器、轴承、橡胶元件、耗材;控制系统和信息转换器;模具及附件。

设备和配件的维修和服务;现代信息CALS技术的发展:科学研究项目、技术和设计的发展、生产管理。

金属加工材料;金属加工科技论文和行业广告宣传;转包和投资项目;金属加工专业培训和生产。

展会报告(Show Reports):

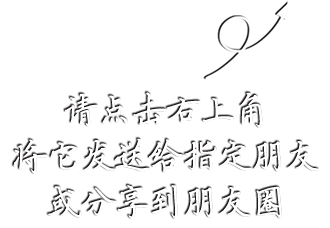

Denis Manturov, Deputy Prime Minister of Russia - Minister of Industry and Trade of Russia, visited metalloobrabotka 2023, the largest International Exhibition for Equipment, Instruments and Tools for the metalworking Industry.

The exhibition included lathes, milling machines, grinding equipment, CNC machining centres, etc. by domestic manufacturers, which were demonstrated to Denis Manturov. More than 35,000 people visited the exhibition over 3 days and more than 1,000 companies took part, 700 of them were domestic companies.

The industry is growing rapidly. Production of machine tool products now stands at more than 60 billion rubles.

“Last year, the government provided support to manufacturers of machine tool products in the amount of almost 2 billion rubles (including compensation of costs for provision of discounts), including 1.4 billion rubles for R&D (and the total amount including investments in R&D of the industry enterprises exceeded 2 billion rubles). We will continue to provide support this year: the results of this year’s R&D subsidy selection will be summarised in June. Because of the state support, this year’s production has already shown good dynamics in the first four months: the growth rate is over 25%. In general, last year we finished with a 24% growth in machine tools,” said Denis Manturov.

Today, domestic machine tool companies are actively developing their own solutions. For example, STAN presented WAMeco, the first CNC machine model for diamond grinding of carbide inserts used in the tool industry. Its peculiarity is that it can be operated fully automatically without human intervention. The Deputy Prime Minister was shown AVEA-TECHNOLOGY’s zero-based systems, which allow to significantly reduce the time for machine re-equipping. Laser Systems put on display additive selective laser melting machine M250 equipped with proprietary software. The development of Eidos Robotics has been unveiled. The company has already introduced its industrial robots at KAMAZ and SIBUR. The company’s spherical robot A12 operates to facilitate proper dispensing of reagents in COVID-19 testing at a Japanese laboratory, which introduced it in 2020. The robots are also supplied to the UAE. The robot has a competitive cost and manufacturing time advantage over a number of foreign counterparts. Delta-Test Scientific and Industrial Corporation showed the ARTA eCut 400 high precision wire-cutting system.

At the end of the visit, Denis Manturov was shown a new five-axis vertical milling centre made by UZTS, with a fully Russian CNC system Mechatronica, a Russian-made spindle and other components. The machine has a very high degree of localisation. It has become possible to develop such a machine thanks to the support of the Russian Ministry of Industry and Trade (as part of Decree No.1649 of the Government of the Russian Federation of 12 December 2019), under which UZTS was granted a subsidy of 100 million rubles.

-

姓名:Angela

-

传真:+86 755 23981406

-

邮件:info@18sz.com

-

QQ:1437816437

-

如遇无效、有误、错误信息,烦请您指正纠错

-

14122个月前

-

15272个月前

-

1397个月前

-

967个月前

-

39789个月前

-

1359个月前