2024年德国国际汽车内饰博览会

-

日期:2024-12-03~2024-12-05

-

城市:斯图加特

-

地址:斯图加特国际展览中心

-

展馆:斯图加特国际展览中心

-

主办:UKIP媒体与活动有限公司

-

德国斯图加特国际汽车内饰博览会(Automotive Interiors Expo )是欧洲最专业的汽车内饰设计及贸易展览会,该展成立于2012年,一年一届,在斯图加特国际展览中心举行,该展以引进更多的参展商和更多的技术,有力地提升汽车内饰设计和制造业,并因此创造这个展览,这是一个卓越的汽车内饰件展,为汽车行业的聚焦中心。与其它四个汽车相关展同期举行(汽车测试展、汽车引擎展、汽车配件供应展等),吸引更多专业人士及观众。

汽车内饰博览会将汇集世界领先的方法和方法两个厂家之一,在一个高度专业化的展览和会议的最新发展和产品为汽车内饰社区推出。从世界一流的汽车像CabAuto和条状照明厂商如Hitaltech内部元件制造商,像绍尔和紧固的YKK公司的激光切割公司,汽车内饰展览会将汇集汽车制造商和设计师,造型的房子,和全方位的汽车内饰供应商。

斯图加特国际汽车内饰博览会是一个非常具有成本效益的销售和营销平台,我们作为组织者致力于提供业务联系,为每一个参展商创造价值。该展提供了一个高度灵活的环境,可以实现广泛的销售和营销目标,从产生销售线索,推出新产品,建立品牌形象,维护客户关系和任命新代理商。凭借丰富的曝光机会,从展位和赞助,论坛,比赛和奖励,以及我们的网站,我们为您的销售和营销活动提供了一个动态的环境。该展鼓励双向交流,最重要的是,业务是面对面的 - 建立和维持客户关系的最有效方式。

展品范围(Show Products):

座椅,紧固件解决方案,地毯,地板垫,隔音材料,阻燃材料,皮革,织物,在车载娱乐系统,扬声器系统卫星导航系统/远程信息处理,信息娱乐软件提供商,MP3播放/4的兼容性,胶合板,碳纤维贴面,轻质材料,后视镜,化妆镜,遮阳板和遮阳蓬,仪器,室内照明,门板,安全带/约束系统,安全气囊,门槛角线,信息显示,屋顶衬板,驾驶舱和仪表板,包裹货架,引导衬里,装载区系统,杯架铰链(手套盒等),接线织机,电子紧固件,室内门发布,开关和切换,弹簧闩锁(开关设备),暖通空调系统,电源插座,屏幕和显示器,电动马达(机动显示器和太阳的画面),液压支柱,抓住把手,覆盖扣件挡板。

展会报告(Show Reports):

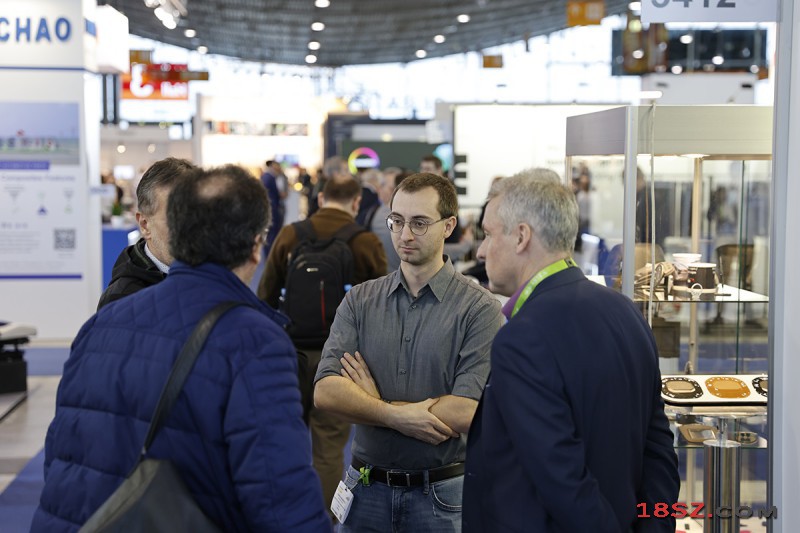

The Messe Stuttgart welcomed visitors, speakers and exhibitors to the 2023 edition of Automotive Interiors Expo Europe on December 5, 6 and 7.

Designers, component manufacturers and suppliers exploring unique automotive interior solutions showcased their latest innovations, with the Technology Presentation Stage offering insights into the latest advancements in coatings, surfaces, materials, screen-printing, haptic technologies and more.

Feedback from Automotive Interiors Expo attendees and exhibitors was notably positive, with many previous visitors to the show making a return to the exhibition. Among those familiar faces was Erkan Simsek, director of R&D and Sales and Quality at Oshino Lamps, who outlined one of the many benefits of the expo: “We have returned to the exhibition for the past 15 years because it is an excellent opportunity meet OEMs and customers. After Covid-19, it is important have face to face exchanges, and the expo is a great place to meet all the right industry experts.”

Attendee Steve Crowe, design manager – studio engineering at Bentley Motors, praised the variety of products on show: “Exploring the range of unique suppliers and the diversity of technology at the show, I’m particularly drawn to low-volume bespoke products – the options here are not only interesting but highly engaging.”

Joost Van De Wouw, CEO at first-time exhibitor Innofa, explained what the company was looking for at the show: “Operating manufacturing facilities in Mexico, the USA and the Netherlands, we specialize in the production of high-quality woven fabrics that are in great demand. Our strategic presence in these at the show allows us to address the escalating market needs through the right customers.”

With sustainability at the forefront of many industries, the show included a focus on the search for more environmentally friendly materials solutions for automotive OEMs and suppliers. Covestro presented its water-based polyurethane coatings for eco-friendly door panels, which don’t compromise on performance or quality.

Munthanarat Chaisorn, marketing communications, specialty films, EMLA, Covestro (below), said, “This show serves as a significant stage for showcasing our latest advancements in automotive interior materials and technologies. Being part of this show allows us not only to demonstrate our commitment to driving toward more sustainable design in automotive interiors but also to establish valuable connections with potential collaborators.”

With its INSQIN water-based polyurethane (PU) coatings, the company offers translucent optical properties, coating adhesion and deep color effects in door panel covers. This aqueous, low-VOC solution has been developed specifically to enable more cost-effective and sustainable applications for the future requirements of car interiors.

Ligneos (above) also exhibited developments using sustainable materials. The company uses natural materials such as wood, premium textiles, stone, cork and other sustainable options to cover larger areas.

The company is developing laminated materials for active surfaces. The sheets undergo enhancing production steps, during which Ligneos precisely laser-cuts them to meet customer specifications. The final products exhibit exceptional adaptability, conforming to various shapes and surfaces, including small radiuses and sharp corners.

Francesco Terzi, a sales engineer at Ligneos, explained, “The possibility of using several materials (wood, stone, textiles) makes Ligneos a strong and reliable partner for OEMs, cooperating with them in each step of the development and validation process.” Terzi said that Ligneos is working side by side with customers, supporting them from material selection until the final approval before serial production.

According to Terzi, the flexibility of the materials helps during the pre-forming phase, creating no cracks and removing the need to rework the parts. All products are crashproof and lightweight, and use sustainable materials including FSC wood and recycled backing.

Representing the epitome of sustainable thinking was show sponsor Scays Group (above), which introduced Wastea, a 100% sustainable, vegan, plant- and bio-based new-generation material made from industrial tea waste. Tea waste would usually be destroyed but it now finds a new purpose as Wastea, which can be integrated into every sector and product where leather, PU and PVC have traditionally been used.

Having undergone rigorous testing, Wastea has already seen success in fields ranging from automotive to textiles, and footwear to bags and accessories, proving its adaptability.

The company also presented another material made from tea, rose, lavender, coffee, lemon, lime, pomegranate, hazelnuts and peanuts.

Erdem Dogan, MD at Scays Group, explained, “A high number of automotive clients have contacted us regarding our new innovation, and we saw the potential to share our sustainable new-generation material. We are replacing conventional environmentally harmful upholstery materials such as real leather, PVC and PU. Our material is suitable for automotive upholstery, which is 100% sustainable, vegan, plant and bio-based.

“Now is the right time to make environmentally friendly changes.”

Grewus offered insight into haptic technologies and demonstrated its new actuator series for haptic feedback, HapForce, which comprises compact and versatile actuators designed to cater to diverse applications. The series is available in three sizes – the HapForce 1, Hapforce 2 and HapForceUlti – and ensures precision and versatility across a spectrum of applications.

Active haptics is more than just a vibration. As Andrea Coric, head of marketing at Grewus, explained at the show, various factors need to be considered to integrate haptics effectively: “Active haptics technology can increase the individual recognition value of a brand while creating a noticeable value in a vehicle’s interior and a personal connection between the driver and the car.”

Electrification is another trend leading the automotive industry. As the world moves toward a more sustainable future, auto makers are increasingly embracing EVs to reduce carbon emissions and combat climate change. Major auto makers are investing heavily in the development of electric models, while governments worldwide are implementing policies to incentivize the adoption of electric vehicles.

This electrification trend extends beyond just passenger cars, encompassing commercial vehicles and the infrastructure landscape, with a growing number of charging stations.

Against the backdrop of the industry’s increasing focus on sustainability and commitment to cleaner transportation, the expo also saw Peugeot exhibit its fresh design concept for EVs. The Inception Concept, from Peugeot’s new design director, Matthias Hossann, focuses on a minimalist cockpit to redefine the driving experience. Crafted exclusively with Stratasys 3D printing technology, the seats are fashioned with a distinctive 3D pattern and upholstered in recycled polyester velvet.

Maud Rondot, a CMF designer in Peugeot’s Advanced Design Team, underscored the Inception Concept’s harmonious blend of function and aesthetics. The choice of a metallic hue for the velvet, with its dynamic interaction with light, introduces a futuristic element. And the Stratasys J850 TechStyle 3D printer, with its ability to produce semi-transparent ‘micro-architecture’, is a transformative tool, providing Peugeot’s innovative design approach with flexibility, efficiency and sustainability.

Another showcase tailored to electric vehicles was Carbody’s latest-generation steering column seal, one of its flagship products. Eric Moreau, sales director at Carbody, said, “We’re developing it with electrification in mind, which is a topical issue. Let us not forget that the key objective of this exhibition is to promote new trends and define developments for the coming year.”

The main challenge associated with the steering column was improving its acoustic performance in size-restricted environments. Moreau said, “This highly technical product is subjected to conflicting requirements. It must be waterproof on the column but without friction, combined with good acoustic performance despite compact dimensions. Often made of plastic, rubber and foam with sealing and acoustic properties, it’s a good resume of Carbody’s know-how.”

Other notable highlights included Xjera Lab’s AI system to streamline inspection processes, XAutomate (above); Mebant’s insulator solutions; San Fang Chemical’s introduction of its latest TPO series; and Sanken’s BEV-tailored interior and exterior materials.

The Technology Presentation Stage saw a variety of speakers share thoughts and ideas on topics as wide-ranging as sensor solutions, smart and sustainable materials, design philosophy and optics.

A highly anticipated presentation on Day 1 of Automotive Interiors Expo, saw McLaren Automotive senior design manager Steve Crijns outline the auto maker’s design philosophy.

“Feeling is a ‘black art’, and design is not an exact science – it’s about creating a feeling of engagement,” he said in an interview at the show. “Engineers do the mathematics, but designers want the car to feel more exciting. But feeling cannot be proved nor measured. Designers have to sell the design within the company first. Developing a design simultaneously with engineering is of the utmost importance.”

He continued, “My presentation expanded on the unique challenges that come with designing a McLaren interior, such as the specific ergonomics requirements for driving at high speed on a track, and how interiors can make the driving experience more engaging. A sports car is enjoyable to drive because of its performance, but it’s not just about numbers and the engineering and technical side, but also how the power is delivered. When you sit inside and experience the car, it’s about how it feels.

“As a driver you want to feel at one with the machine. The interior is where the driver can truly experience the car and engage with it. Interior design plays an important role here to maximize the connection between the driver and the car.

Steve also talked about the future of interior design, challenges such as electrification, and opportunities such as augmented reality and the digital experience. He concluded his presentation with insight into the future challenges for supercars with regard to electrification and legislation, but also the opportunities that autonomous driving and augmented reality can offer to make McLarens even more engaging.

Sustainability continued as a key trend in many of the presentations. Nicolas Samson, senior sales manager for automotive interiors at Bcomp, spoke about how flax fibers create lighter and more sustainable interior components and outlined the importance of reducing the environmental footprint of materials and the weight of vehicles to decrease energy consumption in operation. Bcomp’s composite reinforcements, using flax fiber, offer a solution for automotive interior panels that addresses both of these aspects. These technologies, demonstrated in vehicles like the Volvo EX30, Polestar Precept and McLaren’s F1 seat, present alternatives to conventional solutions, drawing inspiration from natural materials.

Tetsuma Deguchi’s presentation covered eco-friendly plating that does not involve hexavalent chrome (Cr6). Taiyo Manufacturing’s assistant manager explained how the company’s non-hexa is a unique technology that enables decorative chrome plating for automotive components that does not hexavalent chrome during the whole plating process.

Since the REACH regulation restricted the use of Cr6 in 2017 and established a sunset date in 2030 for its usage in the European Union, alternative manufacturing methods for plastic components without Cr6 usage has been a hot topic. Mass production with Taiyo’s non-hexa tech started in 2022 and has been active ever since.

Automotive Interiors Expo Europe 2023 highlighted both innovative technologies and a significant commitment to sustainability in the automotive sector, with this emphasis on sustainable materials and processes demonstrating a collective effort to create environmentally conscious automotive interiors.

Next year’s show will take place in Stuttgart on December 3, 4 & 5, 2024, at the Messe Stuttgart, Germany.

-

姓名:Angela

-

传真:+86 755 23981406

-

邮件:info@18sz.com

-

QQ:1437816437

-

如遇无效、有误、错误信息,烦请您指正纠错

-

562个月前

-

2371年前

-

2261年前

-

3362年前

-

5173年前

-

23593年前